Being at the top in wholesale jewelry manufacturing, Empire Casting House remains dedicated to producing only the finest items befitting the highest standards of quality and design. Empire Casting House commits to excellence in all phases of jewelry manufacturing—from concept to product. This comprehensive guide shall walk one through these complex steps in making beautiful jewelry—from concept to custom design to mass production.

A Legacy of Craftsmanship

With years of expertise, Empire Casting House has mastered the craft. We specialize in craftsmanship to transform raw materials into beautiful art. We believe that every piece of jewelry articulates a story, and we are here to help you craft stories that will be cherished for generations to come.

A Commitment to Quality

Quality is woven into the very fabric of our operations. Right from the meticulous selection of materials to the deft hands of our craftsmen, we are in strict conformance with the best standards. Our ultramodern facilities and high technology ensure that each piece that goes out is precise and uniform.

Partnering for Success

We believe in strong business partnerships with our clients. Working together, we take your special vision and turn it into a concrete, beautiful piece of jewelry. For this, whether you need custom design or ready-to-wear, we have a complete package of services to help your business grow.

Following sections: We shall follow up on the detailed process of jewelry manufacturing—from an idea’s first spark to the final polished product.

Jewelry Manufacturing Process

Design and Concept Development

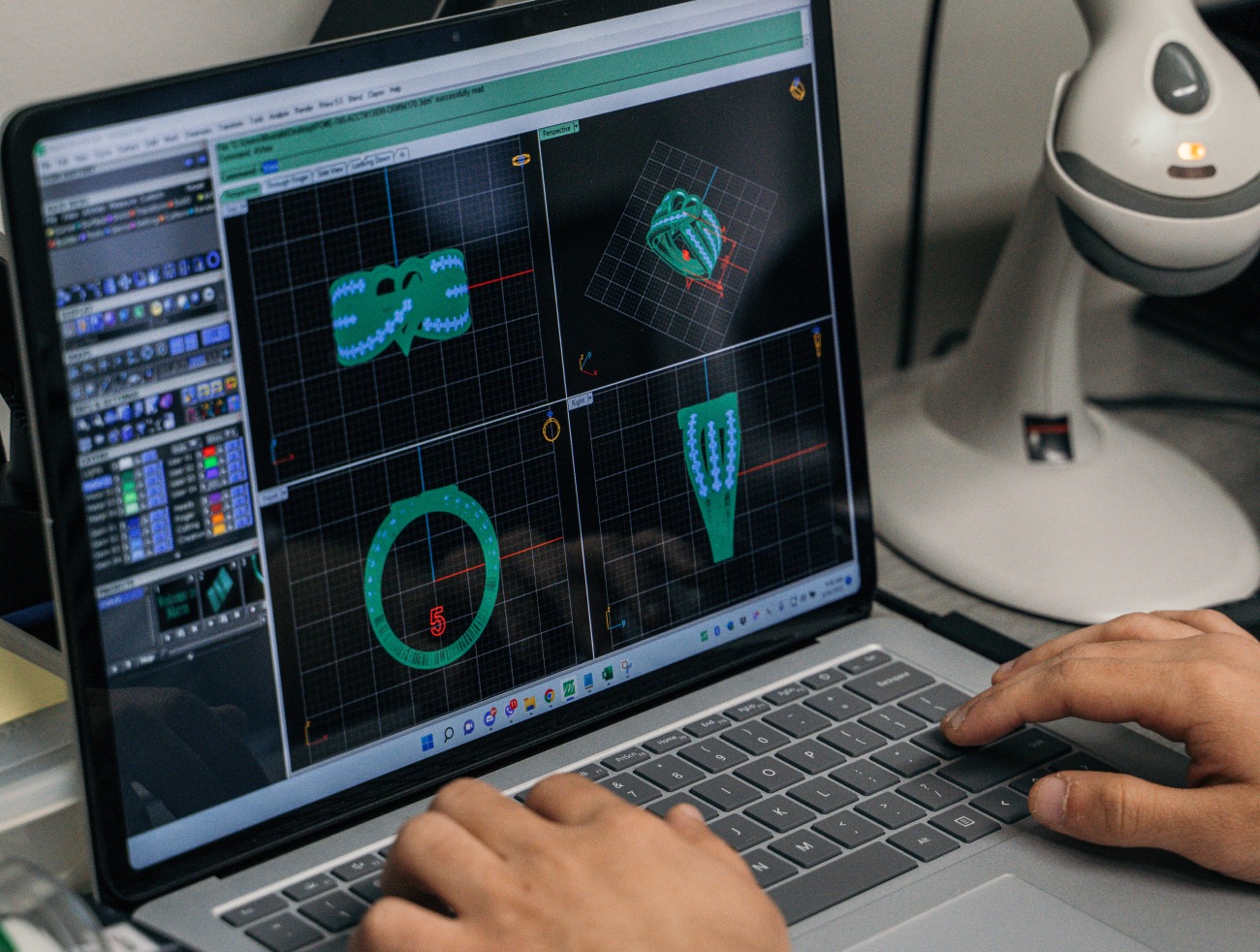

Each item of jewelry has its origin in an idea. Our creative designers work closely with clients to bring their concepts to life. With sophisticated 3D CAD software, we create detailed renderings for ultimate visualization and modification. This step-by-step process ensures that the final design is precisely what the client had envisioned.

What would be considered at this stage is as follows:

Client consultation: Understanding client preference, target market, and budget

Trend analysis: the incorporation of current and/or emerging jewelry trends

Design innovation: The invention of unique and distinct pieces

Technical feasibility: A design that can be easily produced and cost-friendly

Upon the completion of design, we create a digital blueprint that becomes the basis for the following steps of our manufacturing procedure.

Wax Modeling and Prototyping

After finalizing the design, a wax model will be made. This is considered a blueprint for your finished product. Our artisans painstakingly handcraft the wax model so it exactly conveys the design.

A wax model is sculpted to bring the digital design into physical manifestation. This is where the magic happens—the artistry and mastery of our craftsmen come to life. Each wax model is handcrafted by our skillful artisans, taking the necessary care that it is an appropriate representation of the intricate details of the design.

Key aspects of wax modeling

Material selection: The type of wax that is used is directed by the desired outcome of the product.

• Hand carving: Accurately and delicately shaping the wax model.

• Detailing: Adding fine details and textures to the model.

• Quality control: Checking the wax model for its accuracy and flawlessness.

Once ready, this wax model will form a base for the casting process. This kind of attention to detail ensures that the end product reflects an accurate presentation of what one had in mind.

Casting: Bringing the Design to Life

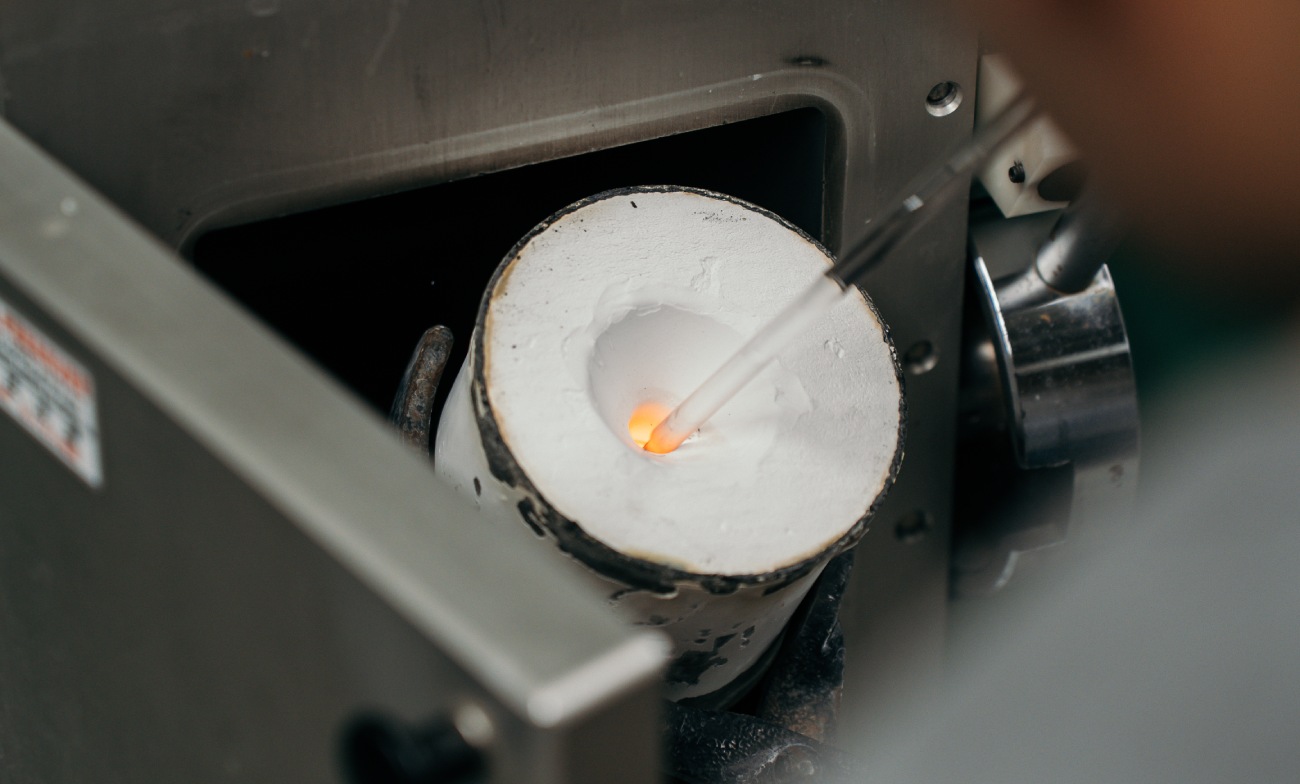

The mold encases the wax model and is then heated to melt the wax and leave cavity air in the correct shape. Molten metal, in the form of gold, silver, or platinum, is poured into this mold to form the basic shape of the jewelry.

More precisely, casting is an extremely critical part of turning this wax model into something tangible in metal. This intricate process has these key stages:

• Investment: The model in wax is carefully placed inside a ceramic investment material. This forms some sort of mold.

• Burnout: The investment mold is heated to high temperatures, melting and removing the wax to leave behind the cavity in the form of the desired piece.

• Metal Melting: The chosen metal, such as gold, silver, or platinum, is melted to a liquid state.

• Casting: The stream of molten metal is poured into the investment mold to fill the cavity and take the form of the original wax model.

• Cleaning: After cooling, the metal is revealed by cleaning the investment material from it.

Casting is a delicate process that calls for precision and expertise. State-of-the-art facilities for casting along with skilled craftsmen ensure that each piece can be produced under utmost care and attention to details.

Finishing and Polishing

It undergoes a very detailed process of finishing to remove the imperfections and achieve the desired glow. As such, it involves techniques such as sanding, polishing, and buffing.

The casting process yields the jewelry piece in raw form. For it to become a polished masterpiece, thorough finishing and polishing are required. There are a few steps in this stage:

•Cleanliness: Removing investment material or any residue left over from the casting process.

•Grinding: This technique is used to smooth out rough surfaces and remove excess metal.

• Filing: Reshape and contour the piece.

• Polishing: It features a variety of methods that give a luster finish. It includes buffing and tumbling

• Hand finishing: Finish the piece with the addition of last details to improve the appearance of the piece.

We are expert craftsmen who apply a blend of traditional and modern methods of completing an item to get the desired result. Whether it is matte, satin, or high polish, we can do the perfect finish for you to accent the design.

Setting

After that, these gemstones or diamonds are set into jewelry pieces using methods like prong, bezel, or channel settings. Our expert craftsmen ensure that the stones are placed securely and beautifully.

Gemstone Setting: The Art of Enchantment

Setting a gemstone requires finesse and skill to change a simple piece of jewelry into an alluring piece. The style of setting drastically changes the overall look and brilliance of a gemstone.

The usual techniques for setting include:

• Prong setting: This is the oldest of the methods, whereby a gemstone is held in place by metal prongs that simply grasp the stone from the top, allowing maximum light to enter the stone and increase its brilliance.

• Bezel setting: A ring of metal surrounds the gemstone, creating a covered, sophisticated look.

• Channel setting: The gemstones are placed in a continued groove or channel, creating a line of sparkle.

• Pave setting: These are small stones that are set so closely together as to completely cover the metal surface and give it a brilliant look.

• Invisible setting: The gemstones in this setting are so closely set that the metal is barely noticeable, creating a fluid and luxuriant look. A number of steps go into making a setting:

• Preparing the setting: The metal is prepared with an appropriate space for the gemstone.

Setting the stone: The gemstone is maneuvered into the setting, then held in place with prongs, metal beads, or a bezel.

Finishing: The setting is refined to hold the gemstone securely in place, giving the piece an overall perfect appearance.

Our accomplished setters know which style setting to use for each gemstone and design in order to achieve a beautiful, yet long-lasting, piece of jewelry.

Quality Control

Every piece is subject to stringent quality control, whereby it is checked against our high standards of metalwork, gemstone quality, and finish.

Quality control in jewelry forms an intrinsic part of any manufacturing process. Not only does it sustain the highest standards of craftsmanship, but also ensures customer satisfaction at large. In ensuring the upkeep of rigid standards, a string of quality control procedures are followed at multiple checkpoints throughout the manufacturing process.

Some of the key quality control measures that are taken into consideration:

• Design Verification: Checking the final design against the concept and the specifications of the client.

• Wax Model Inspection: This is a check for accuracy, detailing, and quality of the wax model.

• Casting Evaluation: Checking the flaws within the cast piece, including air bubble, metal inclusions.

• Finishing and Polishing Inspection: Standard of finish for its aesthetic appeal and durability.

• Assure that the setting of the gemstones is secure, with proper alignment and good appearance.

• Purity tests on metals to verify their purity/composition

• Dimension and Weight Checking: Check whether the article meets the specified dimensions and weight requirements.

• Functional Testing: Clasps, hinges, or similar mechanisms should be checked for proper functioning

• Verification of the quality and integrity of the Packaging material.

Our quality control team is committed, with advanced inspection equipment and conformation to the strict industry standards. With the establishment of a proper quality control system, every piece of jewelry that leaves our factory shall uphold this excellence to which we are committed.

Plating and Finishing Touches

Various plating processes, such as rhodium or gold plating, can be done to enhance the appearances and durability. Finally, polishing is done followed by quality control checks before the item is packaged.

Packaging and Shipping: The Final Touches

The finished jewelry carefully is packaged to protect it during shipment. With our efficient logistics, we ensure delivery to all our clients on time.

The last process for jewelry manufacturing is the proper and secure packaging of the finished piece to ensure protection during transport and in a display form.

Packaging:

- Selection of packaging materials: Choosing appropriate boxes, pouches, or cases to protect the jewelry from damage.

- Interior protection: Using soft materials like tissue paper, velvet, or foam inserts to prevent scratches and movement.

- Branding: Incorporating the brand identity through packaging design, colors, and logos.

- Information inclusion: Providing care instructions, product details, and warranty information.

Shipping:

• Choice of carrier: Choice of a carrier with history of safe and on-time delivery.

• Safe packaging: The jewelry should be safely packed in the box for shipping. It should not move around the box while it is in transit.

• Insurance: Adequate insurance should be provided on the shipment.

• Tracking: Shipment is to be tracked by means of the tracking services.

Keeping these factors in mind, we make sure our customers’ jewelry is pristine when it arrives and they’re going to have a remarkable unboxing experience.

Semi-Mounts and Mountings: Cornerstones of Customization

Semi-mounts and mountings are the cornerstones of any jewelry manufacturing. Semi-mounts are simply pre-designed settings without center stones, while mountings mean the complete ring band without the head or center stone. These components bring flexibility and efficiency into jewelry production.

Semi-mounts and mountings offer a versatile starting point for creating one-of-a-kind pieces. These are pre-designed parts, adding a base of various gemstones to be finalized with personalization.

Semi-Mounts

The semi-mount is a ring setting that includes all side stones and design, but without a center stone. It provides a pre-designed framework that allows a specific kind of gemstone to be selected by the jeweler in order to complement an existing design element.

Key benefits of semi-mounts:

• Customization: A jeweler can find the perfect center stone to fit their client’s desires and budget.

• Time-Efficiency: Semi-mounts reduce production time versus a full custom ring.

• Design Variety: Many different styles and designs are available.

Mountings

Mountings are much simpler components that include the ring band but without the stones or any intricate designs. This mounting would be used to create a base for making a custom ring, with the center stone and the setting style one desires in mind.

Key benefits of mountings:

• Versatility: With a mounting, one could set up any kind of centre stone with the setting.

• Customization: The jeweler has an entirely free hand to decide how a ring will look.

• Cost: Mountings are more economical compared to when one wants to come up with a fully custom-made ring.

Using semi-mounts and mountings gives a lot of flexibility to the designer/manufacturer, all while reducing the number of parts that need to be designed and manufactured.

Custom Jewelry Design and Manufacturing

We deal in made-to-order kinds of jewelry, including those that are made to specification. The customers’ ideas are uniquely taken from them, from concept to completion. Using our high-tech 3D design, we can simulate and pre-refine the final piece until it perfectly reflects your vision.

Your Vision, Our Expertise

To Empire Casting House, in truth, luxury is personalization. We refer to this as a process of Custom Jewelry Design and Manufacturing with our skilled artisans along with you. We bring your unique vision into tangible masterpieces.

The Collaborative Design Process

• Initial Consultation: Begin with your needs, likes, and budget in mind

• Concept Development: Our design team will work with you to create detail sketches and renderings based on your idea.

• 3D Modeling: State-of-the-art CAD technology creates intricate 3D models for visualization and refinement.

• Material Selection: We’ll help you choose the perfect metals, gemstones, and other materials that bring your design to life.

• Design Refinement: We will go through several iterations until this design is brought in complete alignment with your vision.

The Manufacturing Process

After finalizing the design, our skilled craftsmen meticulously bring your vision to life. This includes :

• Wax Modeling: A wax model of the designed piece to be cast is made.

• Casting: Employ precision-casting techniques to turn the wax model into a metal piece.

• Finishing and Polishing: Refine the metal piece to create the desired finish and shine.

• Setting Gemstones: Selectively set your chosen gemstones to enhance brilliance in the design.

• Quality Control: Ensure the highest standards of craftsmanship by rigorous inspections.

The Empire Casting House Difference

• Experience: Our proficient and expert designers and craftsmen are at service to bring your idea into life.

• Personalisation: We offer incomparable personalization options so that clients get truly unique pieces.

• Quality: We commit to excellence from beginning to end in the production process.

• Responsible Sourcing: We have ethical practices in sourcing materials and are committed to longevity with no hint of darkness.

• Client Satisfaction: We believe in building a long-term relationship with our clients by delivering more than what they have expected.

A marriage of your imagination and our expertise will result in uniquely designed custom jewelry that makes for beauty but is also personified.

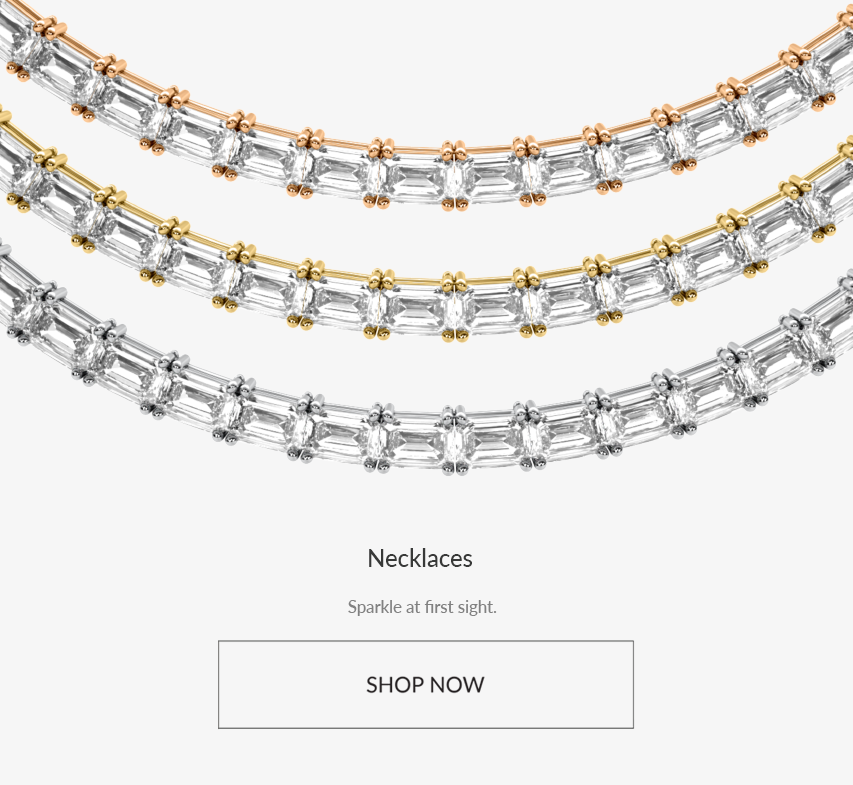

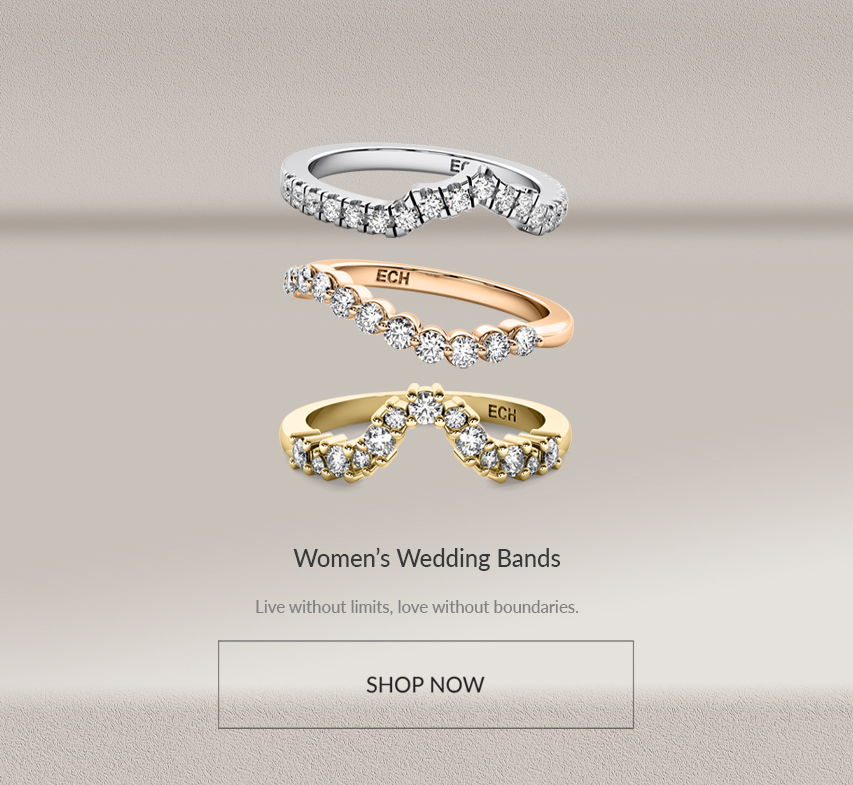

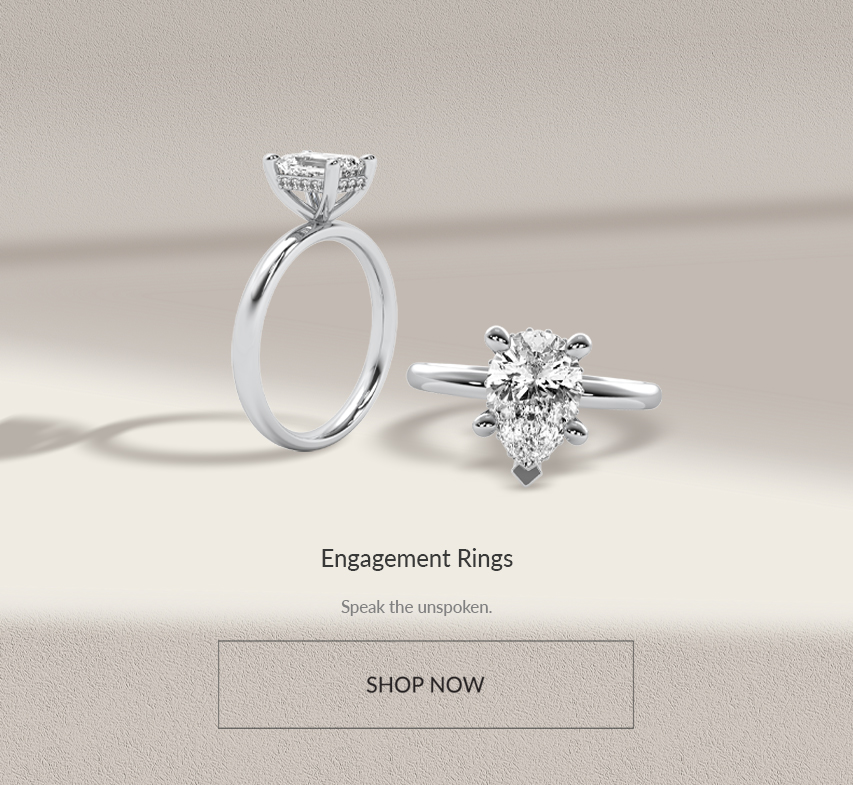

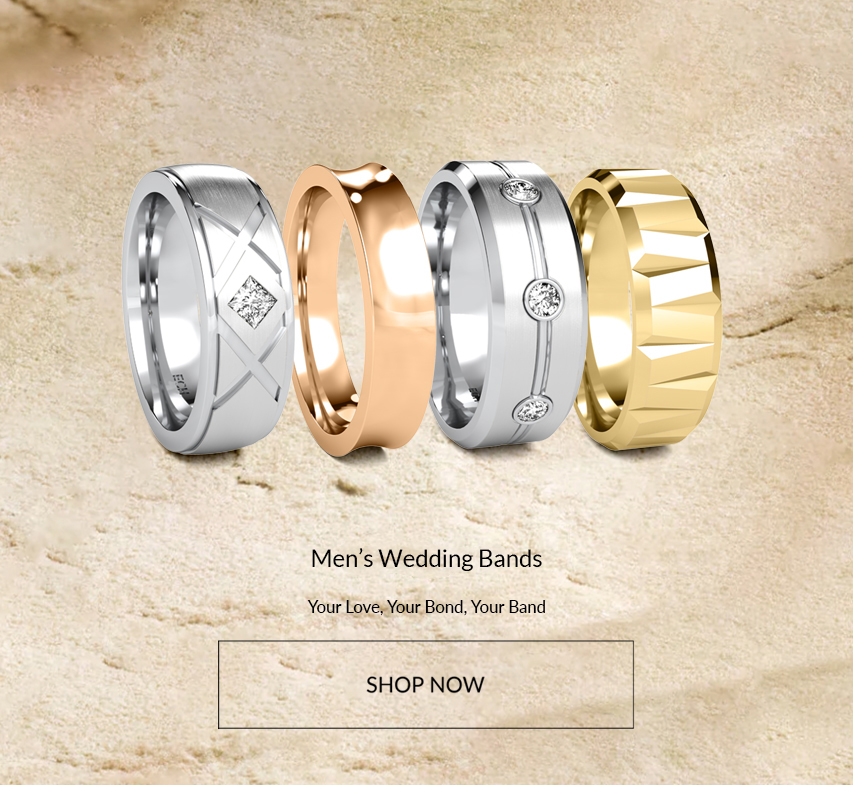

Wholesale Jewelry: Ready-to-Wear Solution

Besides custom design, we have a number of ready jewelry solutions. Our wholesale jewelry inventory includes rings, necklaces, earrings, and bracelets in many styles and taste. These pieces are made to fill various jewelers’ inventories with great efficiency and speed.

The Importance of Ethical Sourcing

Ethical sourcing is part of the business philosophy at Empire Casting House. We believe that our jewelry shall be created in such a way that not only people but also the entire planet is respected and saved.

Key Aspects of Our Ethical Sourcing:

Conflict-free diamonds: We source our diamonds from suppliers who adhere to the strictest ethical standards; therefore, the diamonds we use are guaranteed to be conflict-free and provide positive social impetus.

Responsible Gold Sourcing: We ensure that gold is sourced responsibly in order to preserve our environment from damage and give respect to the welfare of laborers. We are very proud to use certified gold to manifest our commitment to ethical sourcing.

• Human Rights and Labor Standards: We work with suppliers dedicated to maintaining high standards of labor practices in terms of fair wages, safe working conditions, and no use of child labor.

• Environmental Responsibility: Lessen our impact on the environment by working to introduce sustainable practices within our production lines and with suppliers committed to eco-friendly means.

• Transparency and Traceability: We maintain transparent supply chains and deal with partners who have the same commitment toward ethical sourcing.

It’s our way of taking one step toward being a more responsible and sustainable jewelry industry that engenders trust with our customers. We believe ethical practices are not only morally correct; they are core to the long-term success of any business.

We are proud members of JBT, MJSA, RAPNET, and FAIRMINED industry organizations, which underpin our commitment to ethical sourcing and responsible business practices.