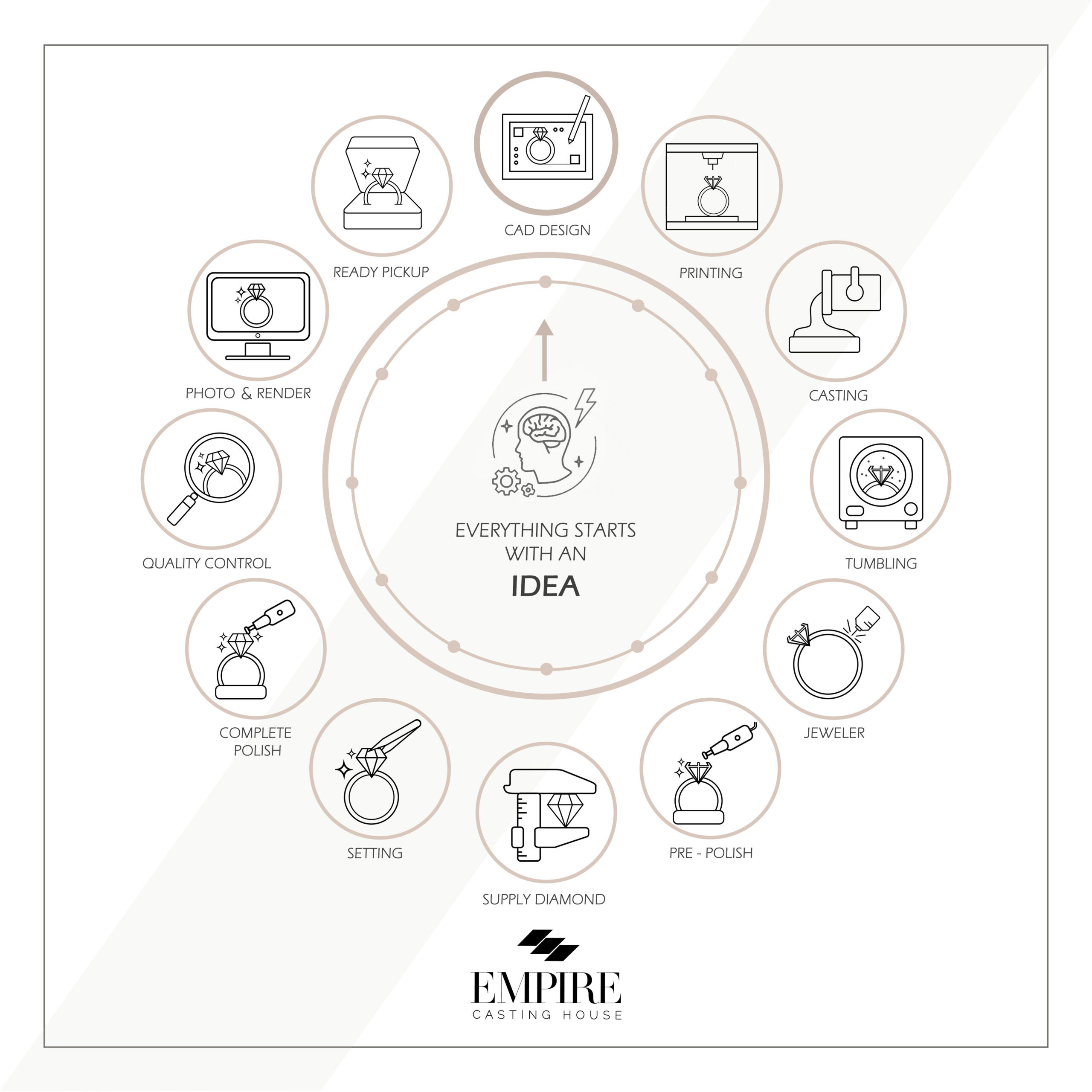

The making of a piece of jewelry is somewhat complicated, with a series of steps involved that are carefully arranged. At Empire Casting House, we pride ourselves on offering a full-cycle jewelry manufacturing service; hence, all the stages involved in bringing an idea from that very first sparkle to the finished and polished piece are covered.

In this article we will list the stages of jewelry manufacturing based on our experience at Empire Casting House.

Here is step-by-step Jewelry Manufacturing

Idea Generation: The Birth of a Vision

Everything starts with the idea-a spark that gets one creative. Our talented designers work in close concert with our clients to understand the vision and translate it into a concrete design concept.

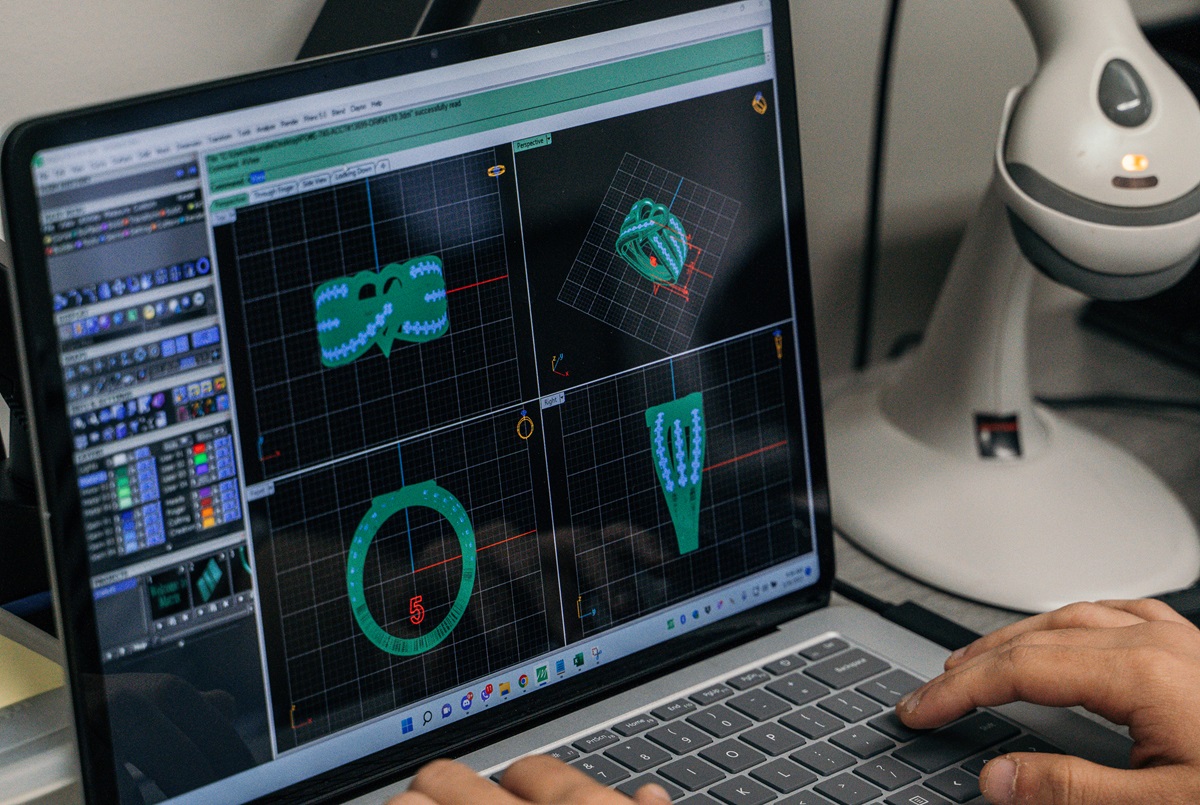

CAD Design: Bringing the Vision into Life

After the concept has been clearly explained, our designers apply advanced CAD software in doing a detail 3-D modeling of the jewelry piece. This enables the correct visualization and modification for perfection to the very specification of the client. You can read this article on CAD Design to learn more.

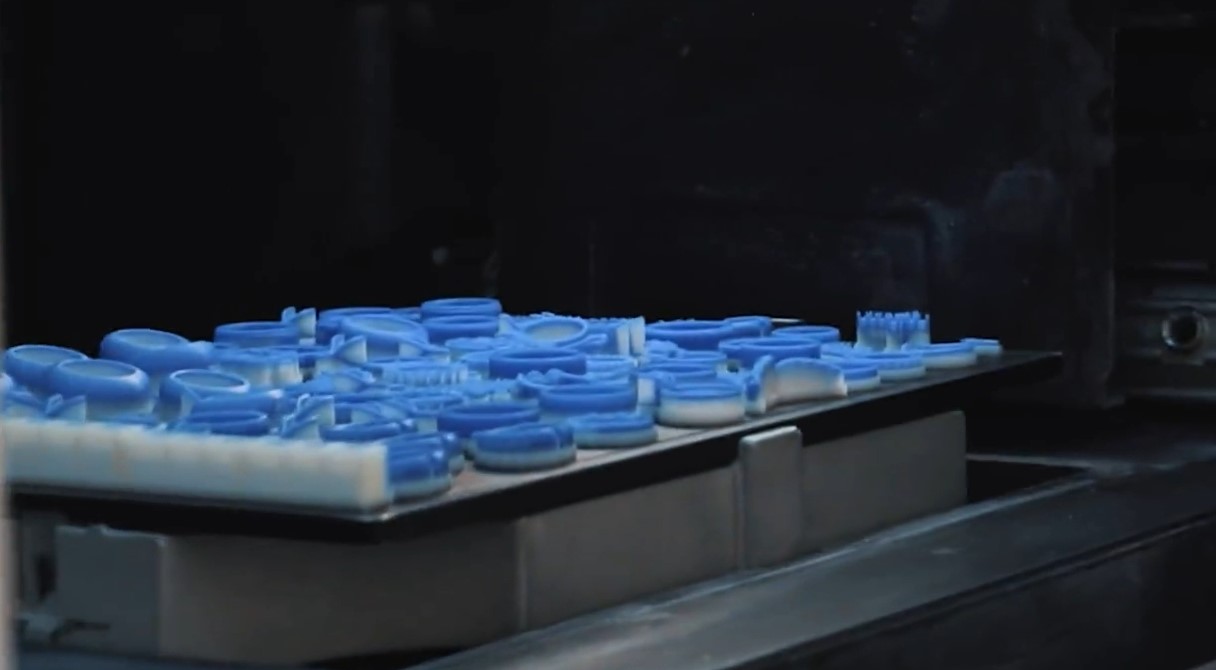

Printing: From Digital to Physical

The model created in 3D is taken to its physical entity through 3D printing technology. This is the step where the design is made tangible, so further refinements and modifications are made before going to the next step.

Casting: Shaping the Metal

From this 3D printed model, a mold is created, and molten metal, such as gold, silver, or platinum, is cast into that mold. This is called casting, a process that gives the metal its desired form as part of the piece of jewelry.

Tumbling: Smoothing the Edges

The roughly cast metal is then tumbled to smoothen out imperfections and ready it for further finishing.

Jeweler’s Touch: The Artist’s Hand

Skilled craftsmen painstakingly check the piece for any adjustment or modification that may be needed. Expertise in this regard ensures the jewelry meets the highest possible standards.

Pre-Polishing: Getting Ready for Perfection

Pre-polishing is a stage at which, with the help of particular tools, the jewelry piece is refined to remove the remaining flaws and gets ready for the setting process. In this stage, the surface will be smoothened, and slight scratches and blemishes are removed.

Provide Diamond: The Heart of the Creation

In case of a design which involves diamonds or for that matter any other precious or semi-precious stone, it is first selected and procured, keeping in view the required characteristic, quality, and cut. As a matter of fact, the quality and cut of these gemstones influence the overall appeal and price of the jewelry to a great extent.

Setting: Holding the Stones in Place

These are securely set into the piece by various techniques-some by a prong, some by a bezel, or channel setting-depending on the design and shape of the gemstone and on the desired level of security.

Polishing: The Finishing Touch

This represents the final smoothening stage where indeed the accessory reaches a really lustrous, perfect finish. This entails giving it a mirror shine, removing scratches and any other blemishes.

Quality Control: Ensuring Excellence

Each and every piece will undergo rigorous quality checks according to our high standards concerning craftsmanship and durability. This concerns the quality of the metals, purity, the quality of the gemstones, and the finish in general.

Photo and Render: Capturing the Beauty

High-quality photos are taken and renderings are made of the finished piece, for marketing, promotion materials, and online sales.

Ready Pickup: Where It All Ends

After the jewelry has passed all quality control processes, it is now ready for pickup or dispatch to the client.

It is this very time-consuming procedure that makes every piece of jewelry designed by us a masterpiece to any of our clients’ expectations.