In the dynamic world of jewelry design or jewelry creation, innovation plays a crucial role in pushing the boundaries of artistry and efficiency. For those involved in wholesale jewelry manufacturing, embracing cutting-edge technologies is essential to remain competitive and meet the evolving demands of the market. Computer-Aided Design (CAD) has emerged as a pivotal technology, fundamentally reshaping how jewelry is conceived, designed, and brought to life. Industry forecasts suggest that CAD/CAM (Computer-Aided Manufacturing) will likely become the standard methodology in jewelry design and manufacturing in the years ahead. For jewelers aiming to enhance their capabilities and streamline their processes, a thorough understanding of CAD is increasingly vital.

One of the most significant advantages of CAD technology is its ability to produce designs with exceptional precision. Every detail, from the delicate placement of a gemstone to the intricate contours of metalwork, can be defined with meticulous accuracy, allowing designers to explore complexities previously challenging to achieve through traditional methods. Furthermore, CAD introduces remarkable efficiency and cost-effectiveness to the jewelry creation process. By enabling digital refinement and visualization, CAD significantly reduces the time and expense associated with traditional mold making and physical prototyping. This technological advancement empowers jewelers to not only amplify their creative potential but also to optimize their operations and deliver greater value to their clientele.

A Modern Approach to Jewelry Design

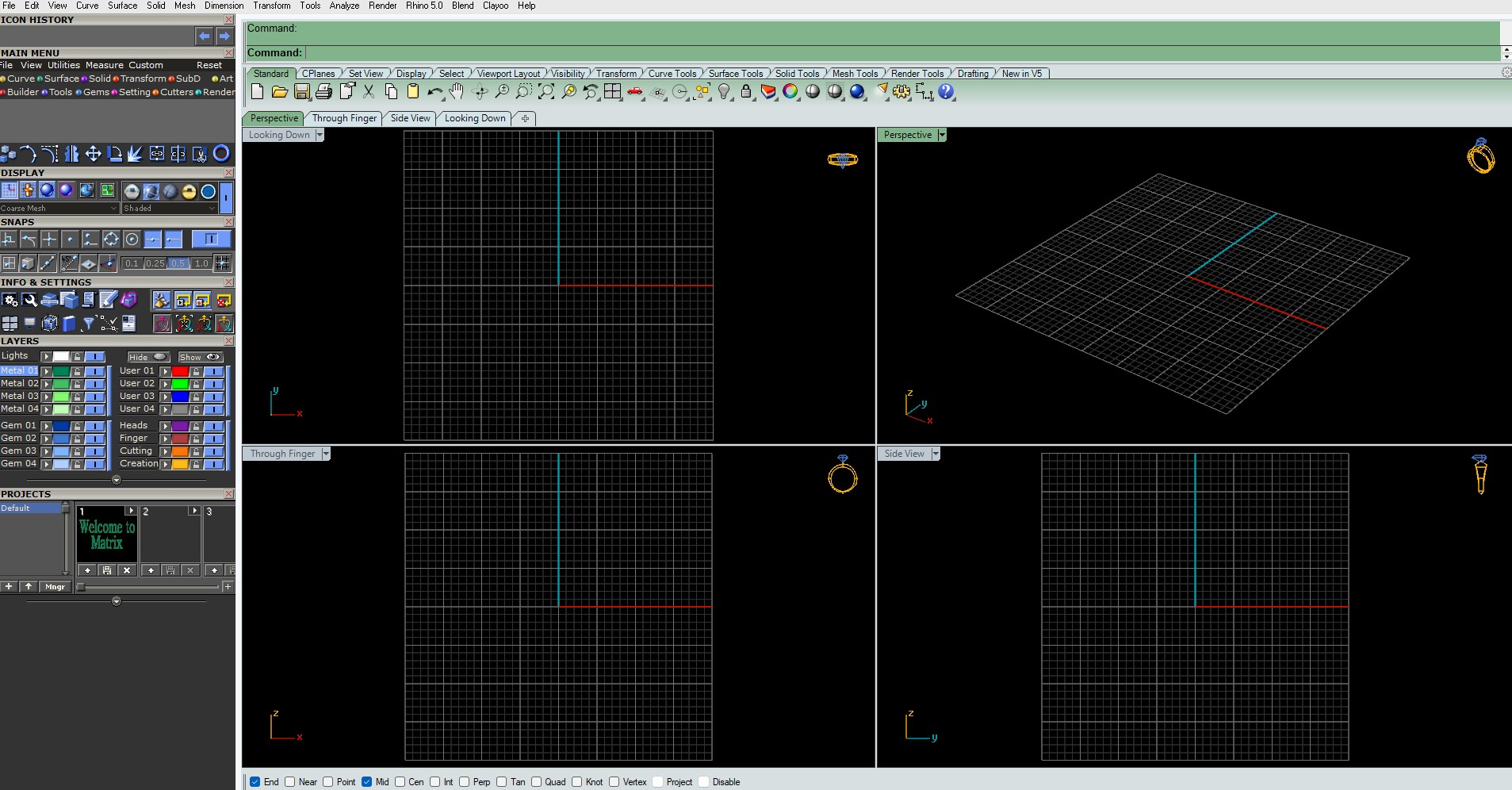

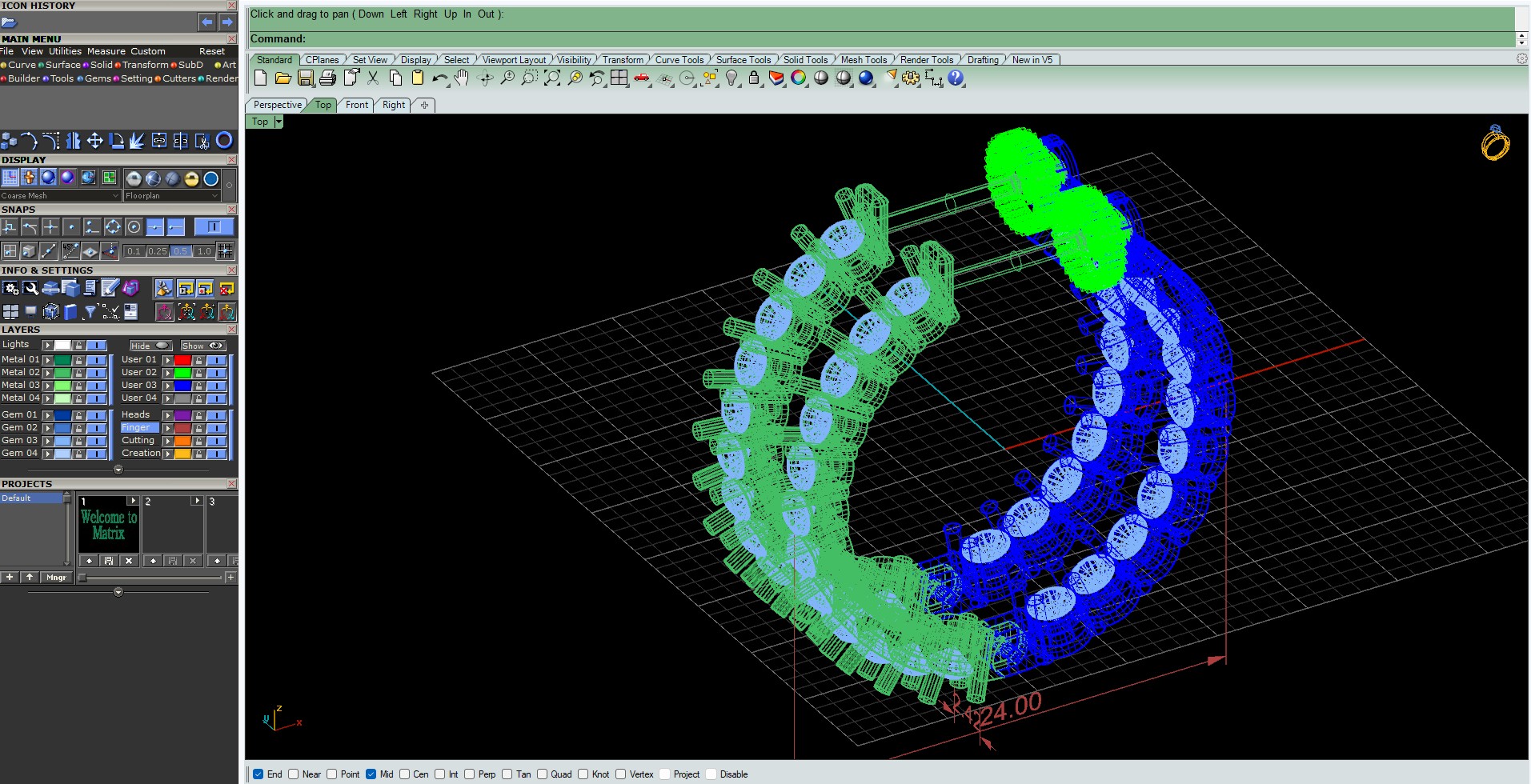

At its core, Computer-Aided Design (CAD) involves the utilization of computer systems to create, modify, analyze, and optimize designs. In the context of jewelry, this means employing specialized software to generate digital representations of jewelry pieces in both 2D and 3D. Unlike traditional methods like hand-carving wax models, which require considerable skill and time, CAD provides a virtual workspace where designers can manipulate forms, dimensions, and intricate details with unparalleled accuracy. This digital approach facilitates functionalities such as mirroring elements, precise duplication, and ensuring symmetry at a microscopic level, tasks that are often arduous and demanding through manual techniques.

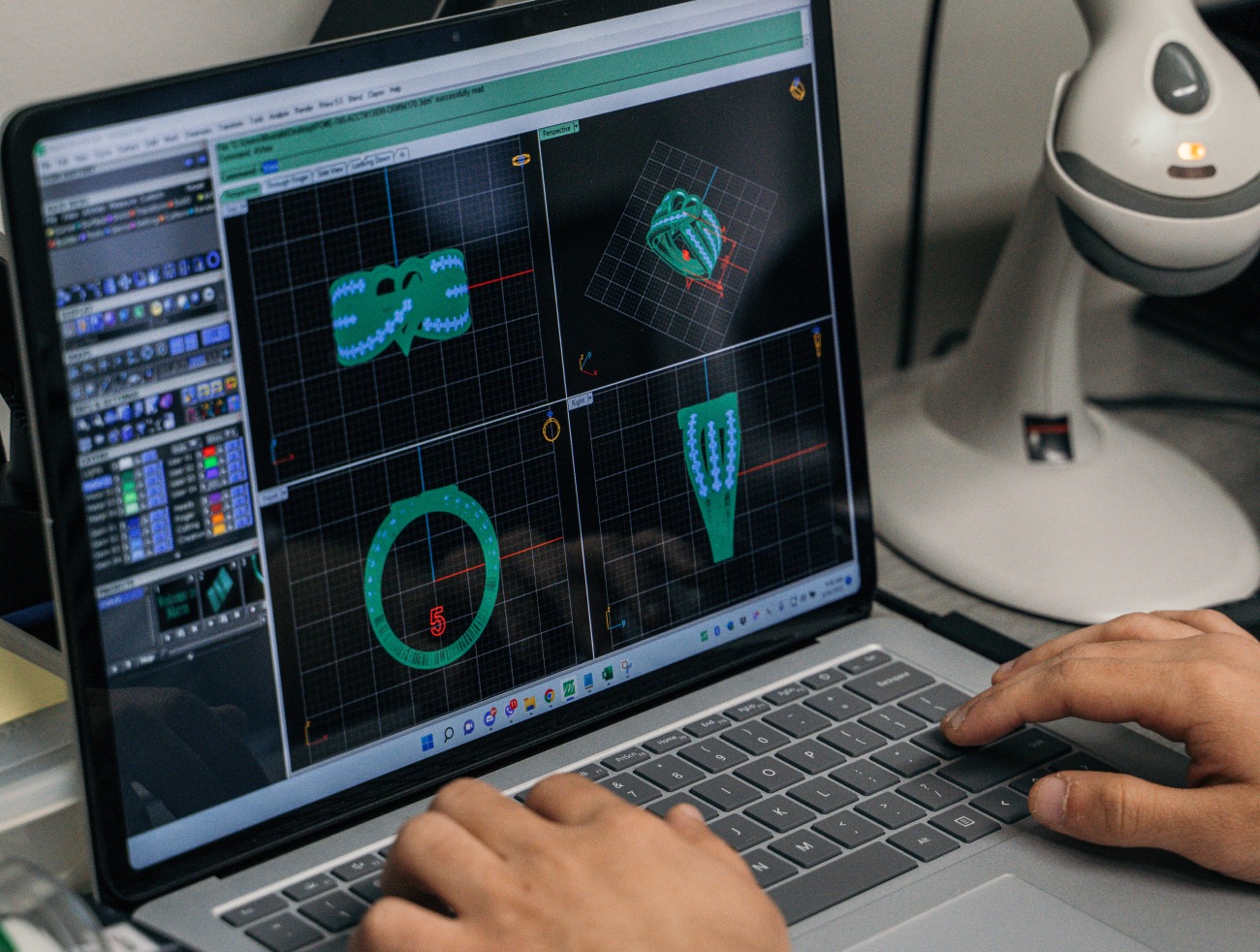

The landscape of jewelry CAD is supported by a range of powerful software solutions, each tailored to different design preferences and technical requirements. Widely recognized programs like Rhino, MatrixGold, and 3Design have become industry benchmarks, offering comprehensive toolsets specifically for jewelry design. Rhino, for example, is known for its versatility in creating complex shapes, while MatrixGold builds upon Rhino’s foundation with specialized features for jewelry construction. 3Design stands out with its intuitive interface designed to emulate a jeweler’s workbench. These software environments typically fall into categories such as solid modelers, which excel in geometric shapes and parametric control, and polygonal modelers, which are preferred for crafting more organic and sculpted designs.

The tools within CAD software enable designers to perform a wide array of tasks, from sketching basic layouts in 2D to constructing fully realized three-dimensional models. Designers can precisely define the dimensions of each component, incorporate gemstones from digital libraries, and even simulate the physical properties of different materials. A particularly valuable feature is the ability to generate photorealistic renderings of the digital models, providing a clear visualization of how the finished piece will appear, complete with materials, textures, and lighting. This capability is invaluable for both the designer in refining their creation and for communicating the design concept to clients before any physical manufacturing takes place.

| Software Name | Primary Use/Focus | Key Features | Target User Level |

| Rhino | General 3D Modeling | Accurate NURBS modeling, real-time visualization, extensive plugin support (e.g., MatrixGold, Grasshopper) | All Levels |

| MatrixGold | Jewelry-Specific Parametric Design | Parametric design capabilities, jewelry-specific tools (e.g., gem setting, shanks), advanced rendering, seamless CAM integration | Professionals |

| 3Design | Jewelry-Specific Design | Intuitive interface, parametric engine, extensive library of jewelry components, photorealistic rendering, 3Shaper sculpting module | All Levels |

| Jewelry CAD Dream (JCD) | Comprehensive Jewelry Design | Hybrid modeling engine, robust parametric system, direct viewport editing, extensive jewelry-specific tools (e.g., pavé, setting, organic shapes), seamless 3D printing integration | Professionals |

| RhinoGold | Jewelry Design (Plugin for Rhino) | Specialized tools for jewelry creation, component libraries, modeling and engraving modules, photorealistic rendering | All Levels |

| ZBrush | Digital Sculpting | Brush-based workflow for organic modeling, high-detail sculpting capabilities, texturing tools | Advanced |

| Blender | Free and Open-Source 3D Modeling | Mesh-based direct modeling, sculpting tools, rendering capabilities, extensive community support | Intermediate to Advanced |

The Multifaceted Benefits of CAD for Jewelers

Application of CAD technology burdens jewelers with a multitude of advantages, altering their whole philosophy of design and manufacturing. Possibly the most important of these advantages is the accuracy and precision that it provides. CAD software enables designers to make drawings with precise measurements and specifications, so every detail, ranging from the positioning of small gems to the cutting of a delicate filigree, is performed flawlessly. This degree of precision reduces the chances of human mistake and variability that can be associated with the use of conventional hand-drafting techniques.

Also, CAD offers unlimited flexibility and complexity to designs. Jewelers can test and realize complex geometric shapes and fluid curves that would be very difficult, if not impossible, to achieve through hand-sketching or carving. The functionalities of the software allow unlimited opportunities for creativity, and as a result, it is possible to make distinctive and creative pieces of jewelry that transcend the boundaries of traditional jewelry aesthetics.

Through the integration of CAD with rapid prototyping and visualization software, jewelers have far-reaching advantage during the design stage. CAD designs can easily be translated into physical prototypes by utilizing 3D printing technology, allowing physical inspection of the shape and fit of the design before final manufacturing. Moreover, the ability to create realistic renderings offers a powerful tool for imagining the finished product, allowing designers and clients to review and refine the design collaboratively.

From both a time and cost standpoint, CAD is far superior to traditional methods. The computerized nature of the design process means an end to material waste in physical prototypes and decreased often inhibitive cost associated with making multiple molds. CAD software also significantly streamlines the design process, which allows for quicker iterations and shorter overall production schedule.

Easy modification and iteration are inherent benefits of CAD. Designers can effortlessly make changes to their digital models, whether it’s adjusting the size of a gemstone, altering the shape of a shank, or exploring different design variations, without the need to start from scratch. This flexibility is invaluable for responding to client feedback and for experimenting with multiple design concepts efficiently.

Finally, CAD enhances improved communication and collaboration throughout the jewelry creation process. Digital design files and photorealistic renderings can be easily shared with clients, manufacturers, and other stakeholders, facilitating clear and concise communication of the design intent. This digital exchange minimizes misunderstandings and ensures that all parties involved are aligned on the final vision, leading to a more streamlined and successful outcome.

Leveraging CAD Design Expertise for Exceptional Jewelry

For jewelers seeking to harness the power of CAD, partnering with experienced CAD designers can be a game-changer. A dedicated team of skilled CAD professionals brings an in-depth understanding of jewelry design and manufacturing, capable of translating even the most complex concepts into precise digital models with meticulous attention to detail.

A collaborative approach is often key to successful CAD design. By engaging closely with jewelers, designers can thoroughly understand their vision, preferences, and specific requirements. Through insightful discussions and detailed consultations, they can lay the groundwork for designs that truly reflect the client’s aspirations. Whether a jeweler has a precise sketch, a collection of inspirational images, or a more abstract idea, an expert CAD team can transform these concepts into captivating digital renderings.

Experienced CAD teams leverage cutting-edge software to ensure the highest level of precision and accuracy in every design. Their expertise allows them to select the most appropriate software based on the specific demands of each project. Proficiency in both parametric and freeform modeling techniques enables the creation of a wide spectrum of jewelry styles, from clean and contemporary to ornate and vintage-inspired. Furthermore, designers possess a deep understanding of material properties and manufacturing processes, ensuring that the digital models are not only aesthetically pleasing but also structurally sound and optimized for production.

Jewelers can leverage CAD services in numerous ways. For those seeking to create unique, one-of-a-kind pieces for their discerning clientele, custom design services offer a seamless pathway from concept to creation. CAD experts can also assist in developing entire new product lines, helping jewelers to expand their collections with innovative and market-ready designs. Additionally, for jewelers looking to update or modify existing designs, a skilled CAD team can efficiently make the necessary adjustments, saving time and resources.

The CAD Design Workflow: Concept to Creation

The process of utilizing CAD design services is typically designed to be transparent, collaborative, and efficient, ensuring that jewelers are involved at every crucial stage. The journey often begins with an initial consultation and idea sharing. Jewelers can reach out with their design concepts, whether through detailed sketches, inspirational images, or simply a description of their vision. Experienced designers then engage in an in-depth discussion to fully understand the client’s preferences, target audience, and any specific requirements for the piece.

Following the initial consultation, designers proceed to sketching and conceptualization. Based on the gathered information, they create initial sketches that capture the essence of the client’s idea. These sketches serve as a visual foundation for the subsequent digital modeling stage. Once the sketches align with the client’s vision, the team moves to 3D modeling and rendering. Using state-of-the-art CAD software, designers meticulously build a detailed three-dimensional model of the jewelry piece. This digital model is then rendered to create photorealistic images, providing the client with a clear and accurate preview of the final product from various angles.

Client review and feedback are integral parts of the workflow. The 3D renderings are shared with the jeweler, encouraging them to review the design and provide their valuable feedback. This iterative process allows for open communication and ensures that the design is progressing in line with the client’s expectations. Based on the feedback received, designers undertake revisions and adjustments. They work closely with the client, incorporating their suggestions and making the necessary modifications to refine the design. This cycle of review and revision continues until the jeweler is completely satisfied with the digital model, leading to final design approval. Once the design is approved, the CAD team prepares highly accurate technical drawings for manufacturing. These detailed drawings serve as a precise blueprint for the manufacturing team, ensuring that the physical piece is produced exactly as envisioned in the digital model.

CAD and the Manufacturing Ecosystem

The true power of CAD lies not only in its design capabilities but also in its seamless integration with other crucial stages of jewelry manufacturing. The precise digital models created through CAD serve as the foundation for various downstream processes, ensuring accuracy and efficiency throughout the entire production cycle. One of the primary integrations is with 3D printing. The STL files generated from the CAD software are directly fed into advanced 3D printers, which then create physical prototypes or castable models, often in materials like resin or wax. This rapid prototyping capability allows jewelers to hold a tangible representation of their design, evaluate its form and fit, and make any necessary adjustments before mass production.

These 3D-printed models play a pivotal role in the casting process, particularly through the lost-wax casting method. The printed wax or resin model is carefully encased in a ceramic investment material, creating a mold. This mold is then heated to a high temperature, melting away the wax or resin and leaving behind a cavity in the precise shape of the jewelry design. Molten precious metals, such as gold, silver, or platinum, are then poured into this cavity, taking the form of the original CAD-designed model. The accuracy of the CAD model directly translates to the precision of the cast piece, ensuring that even intricate details are faithfully reproduced.

Furthermore, the precision inherent in CAD designs is crucial for the accurate setting of gemstones. The digital model specifies the exact size, shape, and placement of each stone, guiding the creation of precise settings in the cast metal framework. This ensures that gemstones are securely held and beautifully showcased, enhancing the overall aesthetic and durability of the finished jewelry piece.

The ability to offer a fully integrated suite of services, where CAD design seamlessly flows into 3D printing, casting, and setting, all under one roof, provides a significant advantage. This comprehensive approach minimizes the risks of miscommunication and errors that can arise when working with multiple vendors, ensuring a smooth and efficient transition from the initial design concept to the final, exquisite piece of jewelry.

Essential Tips for Jewelers Utilizing CAD in Their Workflow

For jewelers looking to incorporate or enhance their use of CAD in their workflow, several practical tips can significantly improve their design process and manufacturing outcomes. Firstly, it is crucial to start with clear and detailed sketches or briefs. Providing as much information as possible, including stone counts, sizes, finger sizes, metal types, and even sample images, ensures that the CAD designer has a comprehensive understanding of the desired outcome.

Secondly, jewelers should consider manufacturing limitations early in the design process. Understanding the intricacies of 3D printing, casting, and stone setting will help in creating designs that are not only visually appealing but also practical and manufacturable. Collaborating with experienced CAD designers who also possess bench jewelry experience can be invaluable in this regard.

Paying close attention to scale and dimensions within the CAD software is paramount. Ensuring that all components of the design are accurately sized and proportioned is essential for the final piece to fit correctly and have the desired aesthetic balance. Utilizing the rendering capabilities of CAD software for visualization and client communication is highly recommended. Photorealistic renderings allow both the jeweler and the client to preview the design, identify potential issues, and make informed decisions before production begins.

Having good file management, such as saving often and maintaining well-organized files, is crucial in preventing data loss and smooth workflow. Jewelers also need to seek comments from experienced CAD users or manufacturers as they go along. Constructive criticism can prove helpful in indicating areas of potential design flaws or areas where changes can be implemented. Finally, to CAD novices or persons wanting to sharpen their skills, enrolling in CAD training courses will provide an excellent starting point and help accelerate the learning curve.

The Future of Jewelry Design with CAD

Cad usage in jewelry design and manufacturing has ushered in a new era of accuracy, adaptability, and convenience. From the ability to create detailed and intricate designs with the highest accuracy to the spectacular time and cost saving, the benefits of CAD to jewelers cannot be questioned. With the implementation of this cutting-edge technology and in association with experienced CAD professionals, jewelers can achieve new heights in creativity, streamline their production line, and finally provide higher value to their customers.

The future of jewelry design is increasingly digital, and understanding and leveraging the power of CAD is no longer optional but essential for staying competitive in the market.