Jewelry Wax 3D Printing Service

Jewelry Printing, one of the revolutionary technologies in jewelry production, comes across as one of the fastest and most effective ways to turn designs into reality. This innovative technology, which leaves behind the time-consuming and labor-intensive processes of traditional methods, offers jewelers the opportunity to turn their dream designs into concrete models. So, what exactly is Jewelry Printing and how does it make a difference in jewelry production? As Empire Casting House, in this article, we will examine in detail the place of 3D printing technology in the jewelry world, the advantages it offers and how it is integrated into the production process. If you also want to push the boundaries in jewelry production and realize your designs in the fastest way possible, keep reading to discover the opportunities offered by Jewelry Printing technology!

Jewelry Printing Technology and Its Effects on Jewelry Production

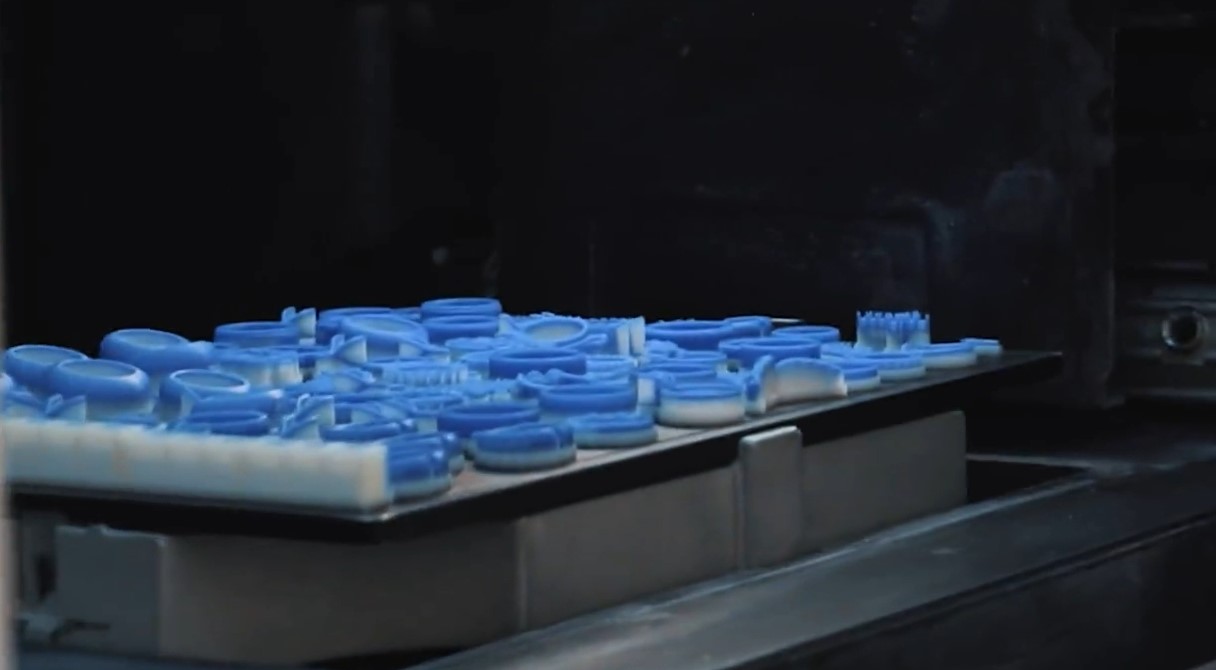

Jewelry Printing refers to the 3D printing technology used in the production of jewelry. This technology is based on the principle of converting digital 3D models created with computer-aided design (CAD) software into physical objects by adding layer-by-layer material. In the production of jewelry, models are produced through high-precision 3D printers, usually using casting-appropriate materials such as resin or wax. As Empire Casting House, we offer jewelers the opportunity to turn even the most complex designs into reality with our state-of-the-art 3D printers and our expert team. Jewelry Printing provides a much faster and more flexible production process compared to traditional methods. A model that can take weeks of manual labor can be produced in a few hours with 3D printing. This allows jewelers to serve their customers faster and adapt to changes in the Sunday more quickly. In addition, the Jewelry Printing technology also offers great convenience at the design stage. Changes made to CAD software can be instantly reflected to 3D models and, if necessary, reprinted. This flexibility speeds up the design process and minimizes the margin of error.

Another important effect of Jewelry Printing technology on jewelry production is that personalized and original designs can be produced easily. Complex geometries and fine details, which are difficult or even impossible to produce using traditional methods, can be easily brought to life with 3D printing.

This gives jewelers the opportunity to offer unique and personalized jewelry to their customers. As Empire Casting House, we turn all kinds of special design requests from our customers into reality down to the smallest detail. Whether it is a ring designed by your customer for a special day, or an original necklace that you are thinking of for your own collection, you can produce the design you want without limiting your dreams with Jewelry Printing technology. The models produced with 3D printing also create an excellent starting point for the casting stage. Thanks to these models produced with high precision, the jewelry obtained after casting is also extremely high quality and detailed.

Jewelry Printing not only speeds up the production process and allows for original designs, but also reduces costs. In traditional methods, while separate molds must be prepared for each model, casting can be done many times over a single model with 3D printing. This, in turn, eliminates mold costs and makes the production process more economical. In addition, material waste is minimized with 3D printing, because only as much material as is needed is used. As Empire Casting House, we are working to reflect these advantages offered by Jewelry Printing technology to our customers in the best possible way. The high-quality resin and candles we use ensure that the jewelry obtained after casting is smooth and flawless. In addition, we adopt an environmentally sensitive production approach by recycling the waste generated during the 3D printing process. All these factors, while increasing the productivity of both us and our customers, also constitute an important step for a sustainable jewelry manufacturing.

Jewelry Wax, 3D Printing Services: Speed, Precision and Quality

Empire Casting House is a leading company that incorporates the most advanced technologies and the most experienced team in the industry in the field of Jewelry Printing. Our New York-based company aims to simplify their production processes and turn their dream designs into reality by providing fast, precise and high-quality 3D printing services to retail jewelers. The latest technology we have 3D printers allow us to produce even the most complex jewelry models with micron-level precision. In this way, we always offer the highest quality models to our customers. As Empire Casting House, we attach great importance not only to technology, but also to human resources. our team specializing in Jewelry Printing approaches each project with great care and attention. We carefully review the CAD files, WAX Model, STL Files and jewelry prototype from our customers and make the necessary optimizations to achieve the best result. If necessary, we will contact our customers, recommend improvements to the design, and go into production after receiving their approval.

Our customers always feel safe when working with us, because they know that their designs are in good hands. One of the most important advantages of Empire Casting House’s Jewelry Printing services is speed. We can make a model that can take weeks with traditional methods ready in a few hours with 3D printing. This speed is of great importance, especially for urgent orders or special occasions. Thanks to Empire Casting House, our customers can produce much faster and increase customer satisfaction compared to their competitors. Our fast production process also reduces our customers’ inventory costs. Thanks to the flexibility of being able to make production to order, our customers can produce as many models as they need, whenever they need. This allows them to use their capital more efficiently and save on storage costs. Moreover, despite our fast production process, we never compromise on quality. The high-quality resins and candles we use guarantee that the jewelry obtained after casting will also be extremely high quality and detailed. The satisfaction of our customers is always the highest priority for us, and for this we pay attention to even the smallest details.

As Empire Casting House, Jewelry Printing we do not limit our services only to speed and quality. At the same time, we offer comprehensive support to our customers. Much more than just a 3D printing company, Empire Casting House stands by its customers at every stage of jewelry manufacturing. In addition to the models produced with Jewelry Printing, we also host all other services such as casting, fastening, polishing. Thanks to this, our customers experience the comfort of entrusting the entire production process to a reliable and experienced team under one As Empire Casting House, Jewelry Printing we do not limit our services only to speed and quality. At the same time, we offer comprehensive support to our customers. Much more than just a 3D printing company, Empire Casting House stands by its customers at every stage of production. In addition to the models produced with Jewelry Printing, we also host all other services such as casting, setting, polishing. Thanks to this, our customers experience the comfort of entrusting the entire production process to a reliable and experienced team under one roof. In addition, we closely follow the developments in the sector and integrate the latest technologies into our manufacturing process.

Ready to Get Started?

Explore our individual service pages for detailed information on CAD design, printing services, casting, tumbling, jeweler services, pre-polishing, diamond supply, setting, complete polishing, quality control, and render services. Contact us today to discuss your unique project and discover how Empire Casting House, your premier New York jewelry manufacturing partner, can help you bring your vision to life.